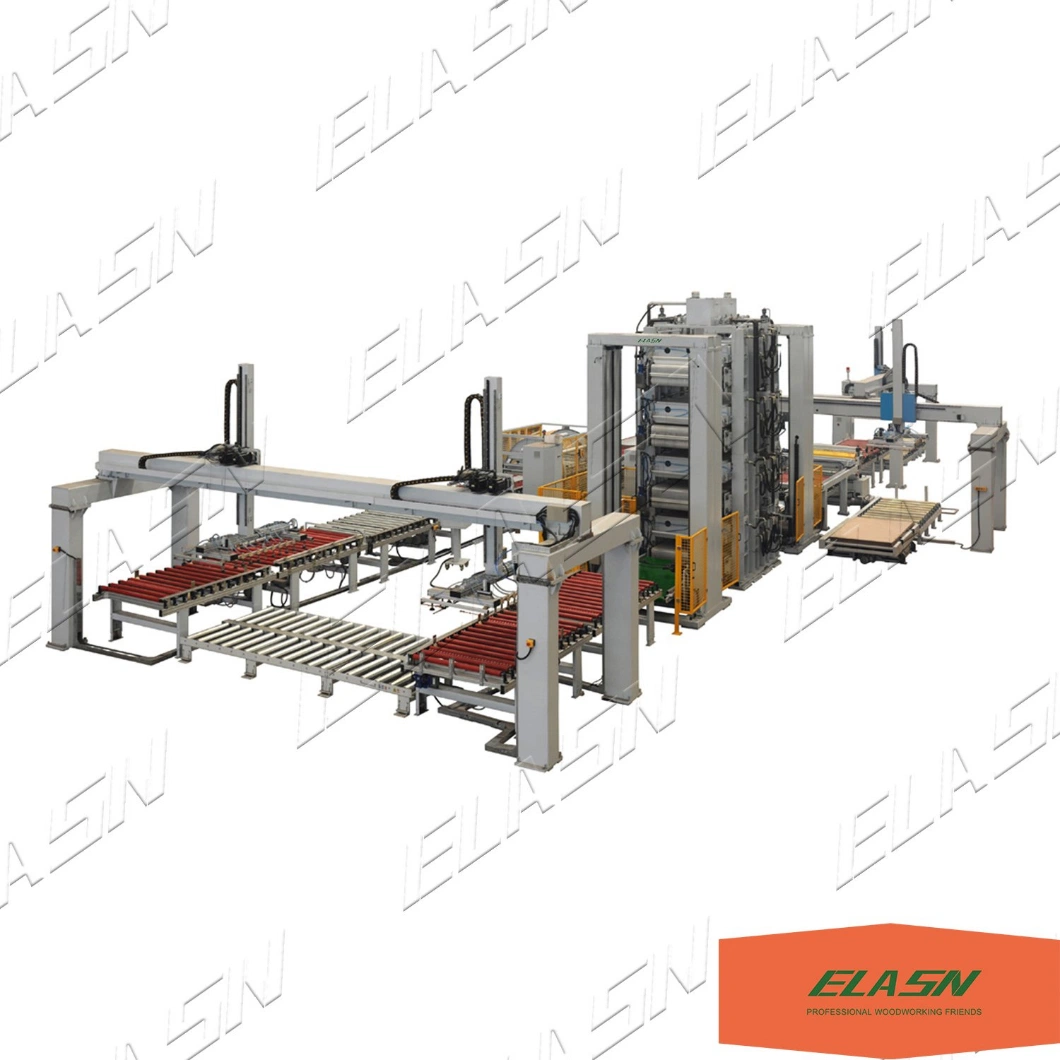

5 Layers Auto Single Layer Solid Wood Electric Laminate Door Skin Hydraulic Press Machine

Description

Basic Info.

| Structure | Frame Type |

| Pressing Shape | Flat Press |

| Platen Surface Pressure | Medium Pressure |

| Pressing Layer | Multi Layer |

| Work Mode | Period |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Certification | CE, ISO |

| After-sales Service | 12 Months Warranty After Goods′ Arrival. |

| Normal Oil Cylinder Diameter | 85mm |

| Normal Oil Cylinder Quantity | 8PCS,10PCS |

| Spacing Between Heating Plate | 70,80,90,120mmm |

| Installation Power | 52.75, 77.5kw |

| Working Layer | 1/3/5/6/Customized |

| Total Pressure | 120/160/200/500ton etc. |

| Heating Methods | Electric Heated with Thermal Oil |

| Heating Plate Quantity | 2/4/6PCS, Customized |

| Application | Woodworking Factory, Door, Furniture Lamination |

| Product Name | Wood Door Veneer Hot Press Machine |

| Transport Package | Load in Container. |

| Specification | 40HQ |

| Trademark | ELASN |

| Origin | China |

| HS Code | 8465990000 |

| Production Capacity | 50 Sets/Month |

Packaging & Delivery

Package Size 3200.00cm * 1500.00cm * 2200.00cm Package Gross Weight 3000.000kgProduct Description

Product DescriptionWood veneer hot press line is used for the veneer lamination of the man-made panels as base material, such as particle board, plywood, chipboard or MDF, with natural wood veneer decorative skin.The optimum lamination quality of various types of panels is ensured by its precise pressure regulation and precise temperature control system.The machine adopts an excellent hot pressing panel, which has good bearing performance and is not easy to deform;The oil pipeline is dredged, heated evenly, and has a long service life.

Single layer hydraulic laminating melamine woodworking plywood mdf laminating hot press machineThe equipment consists of welding frame, multilayer hot pressing plate, tubing, hydraulic cylinder system, electrical control system and other parts.

Multi layer plywood hot press machine mainly consists of hydraulic cylinders, heating plates, press plates, motor, hydraulic valve etc., which can also be customized according to client's requirements.

Detailed Photos

Hot press machine can be used for wooden door fire door veneer, veneer wood skin. Not only suitable for ecological board, particle board, foam board, but also good for density board all kinds of board core secondary surface, such as surface hot pressing, solid wood hot pressing and so on.Effective size of worktable:2500*1300*42 mm;3000*1300*42 mm;3000*1500*42 mm;3600*1300*52 mmBelow veneer press line engineering case for your reference:

Static electricity dust collector sweeper machine

Double side glue coating machine

Double side glue coating machine is used for PVC or veneer decorative gluing of plywood, blockboard core, panel furniture.Hydraulic lifting and stacking table for door press

Hydraulic lifting and stacking table for door press production lineWood Board door turnover machine

Wood Board door turnover machine is applied for trunover and checking the wood door or wood panel after gluing,veneering and pressing in door veneering prodcution line.The electromagnetic valveHydraulic cylinder

Heating platesProduct ParametersMulti layer plywood hot press machine mainly consists of hydraulic cylinders, heating plates, press plates, motor, hydraulic valve etc., which can also be customized according to client's requirements. What's more, this hot press machine can be used for wooden door fire door veneer, veneer wood skin. Not only suitable for ecological board, particle board, foam board, but also good for density board all kinds of board core secondary surface, such as surface hot pressing, solid wood hot pressing and so on. Effective size of worktable:2500*1300*42 mm;3000*1300*42 mm;3000*1500*42 mm;3600*1300*52 mm

| Model | ELA214*9/12(3) | ELA214*8/12(5) | ELA214*8/12(6) |

| Heating way | Electric heatingmedium circulation | Electric heating mediumcirculation | Electric heatingmedium circulation |

| Pressure(KN) | 1200 | 1200 | 1200 |

| Oil Cylinder quantity | 8pcs | 8pcs | 8pcs |

| Oil Cylinder diameter | 85mm | 85mm | 85mm |

| Working layer | 3 | 5 | 6 |

| Spacing between heating plate(mm) | 120 | 90 | 70 |

| Installation power(kw) | 52.75 | 77.5 | 77.5 |

| Maximum pressure ofeffectiveworking area(kgf/cm²) | 3.1 | 3.7 | 3.7 |

| Number and specifications ofheating plates | 4-3000*1300*42mm | 6-2500*1300*42mm | 7-2500*1300*42mm |

| Closing speed (mm/s) | 30 | 30 | 30 |

Remark: There are many different types, for reference, we just show you one type parameter, for more details of other customized models, please contact usDifferent ConfigurationsNumber of layers: 3/5/6 layers.

Application: Wooden door panels, veneer

Operation panel : Electric button operation panel, Simple operation. Equipped with timetable, temperature control meter ,Emergencystop button switch . High safety performance.

Hydraulic station: Germany Hawe hydraulic valve.Safety isolation net: Protect the electrical safety of the machine to prevent accidental touch by the operator

Cylinder : stainless steel design to ensure stability

Hot press panel: Adopt solid driller conduction board, faster and uniform warming

After Sales Service

-The main machine has 12 months guarantee and the electric elements have 6 months warranty. - We respect any feedback from you after receiving the goods.- We promise all spare parts available in lifetime use.- We handle your grumble within 48 hours.

Technical Support

- We have sales teams, together with all technical support from our engineering team.- Before sending machines, test and adjustment service are provided.- Operating video & instruction will be sent to clients for better use of machines.- Any problems occur while using, professional advice will be given by us.

Henan Elasn Machinery Equipment Co., Ltd is located in Zhengzhou, central area of China, a traditional industrial city with rich culture and history. Away from Xinzheng international airport only half an hour, also have train to every main city of China."Business integrity, Quality first" is our principle. Our company is equipped with a professional team of quality control and after-sales service members to keep track of each order scientifically, so as to provide high-speed services for customers."To provide a design, production, quality control, inspection, testing, sales and logistics service to companies that need a reliable supply of wood machinery from China."All members of ELASN welcome new and regular customers to contact us to build long-term and friendly relation of cooperation! We will strive to produce more quality products for you!

Workshop Photo

Customer Feedback

Our Contact