Automatic Insole Making Machine

Description

Basic Info.

| Model NO. | insole making machine |

| Transport Package | Wood Case Packaging, or Customized. |

| Specification | CE |

| Trademark | Hipower |

| Origin | Cn |

| HS Code | 85159000 |

| Production Capacity | 20 PCS/Month |

Product Description

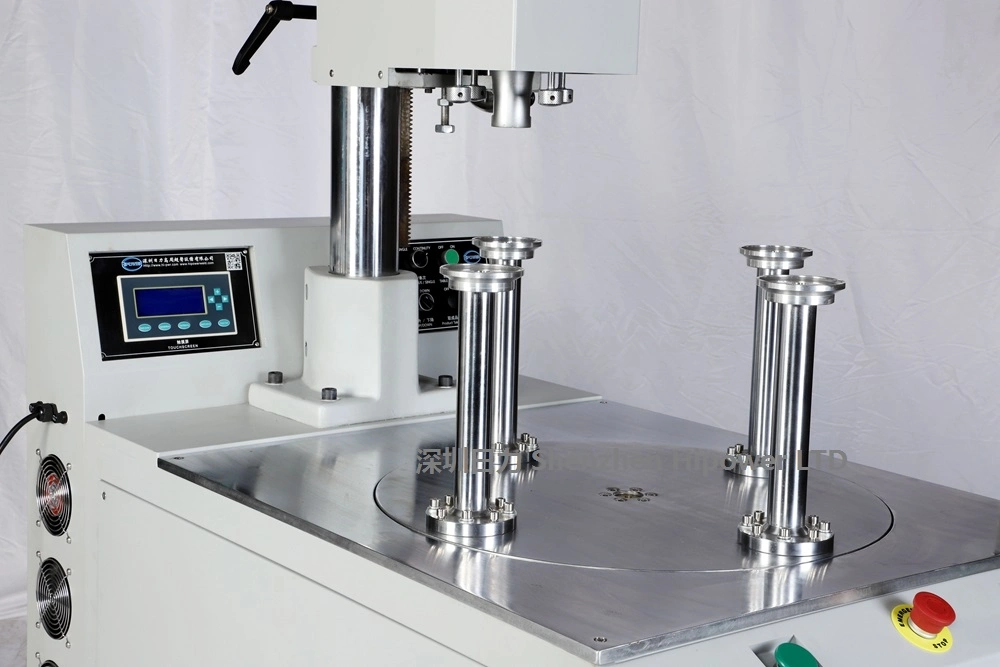

Turn Plate Ultrasonic Plastic Welding Machine, POM Welding Machine, Plastic Welding, PVC Welding Machine

HC-4215Y-4AC Cylinder Bottom Welding/Sealing MachineProduct Description

Application:

PVC cylinder bottom welding, PP cylinder bottom welding, APET cylinder bottom welding, PETG cylinder bottom welding, plastic cylinder bottom welding, paper cylinder bottom welding, paper material cylinder bottom welding, paper tube cylinder bottom welding, transparent plastic cylinder bottom welding; Also known as cylinder bottom sealing machines, ultrasonic cylinder sealing machine, cylinder lid welding machine;

Industrial Fields Applied :

PVC cylinder packing, PP cylinder packaging, APET cylinder packaging, PETG cylinder packaging, plastic cylinder packaging, paper cylinder packaging, paper material cylinder packaging, paper tube cylinder packaging, transparent plastic cylinder packaging. Making ideal cylinders for packaging candy, gift, toy, stationery, umbrellas, packing gear, badminton, snack food and other products

Welded Samples:

Machine General Features:

Four working postion auto turnplate design; precision positioning segmentation;

using the principle of ultrasonic bonding, the effect is strong and beautiful and no scratches.

To meet welding cylinders of different diameter, height, material thickness;

machine operation simple and efficient

| Model: | HY-4215Y-4AC | |

| Power Input: | 3P 380V 50HZ / Custom | |

| Cylinder diameter: | 20mm-200mm | |

| Cylinder Length: | 80mm-1000mm (before curling) | |

| Film Thickness: | 0.17mm-0.5mm | |

| Control System: | PLC+HMI touch screen | |

| Material film applied | PVC, PET-G and other ultrasonic weldable plastic films | |

| Production Speed: | 500 to 1000pcs/ hour ( depend on diameter&height) | |

| Machine Size: | 2800mm*2500mm*1750mm | |

| Standard: | CE Certificate | |

| Packing Information: | Case 01: (L*W*H:1.45*1.25*1.95 m) | |

Who We Are:Since 2000, Shenzhen Hipower Ltd, concentrates on highest quality, on-time delivery, professional technology support,customer-oriented service and competitive price.Where Are our Customers:Our products are mainly exported to Asia, North America, South America, Europe and Africa, and etc....What we do:Our equipments are widely used in industrial application like: Automotive Parts, Stationery, conveyor belts Tarpaulin, BigCovers,Tents products, Tensile structure, Medical Bags, Blister Packaging, Cylindrical Box, and other plastic welding industries.

Hipower is at the forefront of newest technical developments in the field of high frequency and ultrasonic welding

technology, automation of production processes, and other innovative industrial solutions.

a) Customer's site installation, training & maintenance available

b) 3 to 24 hours Online service by Email, Fax, Video Online for basic setup and repairs

c) 12 months warranty for machine, life-long tech. support

d) Recommend equipment of top choice based on your requirements for product;

e) Examining mold drawings on your behalf to confirm optimum structure size meeting the requested process;

f) Providing assistance in manufacturing and modifying tools;

g) Our engineering instruction will guarantee your productive manufacturing of top-quality products.

Questions 02: What about Delivery Time:RE: 3 days for standard machine; and 15 to 35 days for custom machines

Questions 03: Payment Term:RE: We accept payment by T/T, L/C, West Union, Paypal.

Questions 04: How do I inspect your machine quality?RE: We always have real machines ready in stock, We shall meet you at airport, hotel, or railway station.

Questions 05: Is the machine easy to use and maintain in future?RE: Yes, it is; we shall provide instructional manual, videos and engineer support via email or video talk online.

Questions 06. How Do You Pack the machinesRE: Our machines will be packed into after treatment wood boxQuestions 07. Does the machine power voltage meet buyers' factory power source?RE:Frequency: 50 - 60HZ Phases: single phase / 3 phases ; Voltage: 110V / 220V / 380V/ 415V/ 440V / On requestQuestions 9. Could you make die / mould for me, if I buy machine from you?RE: We design and make moulds up to product sample or drawings, we charge the mould price at facory cost price.

Prev: Insole Automatic Cutting Machine for Shoes Making

Next: Mini Size Automatic Eyeleting Pressing Machine for High Hells Shoe Insole

Our Contact