Et

ET-360B Laminate Trimmer Wood Through Feed MDF Full Automatic Bevle Edge Banding Machine Price 1. Brief Introduction: 1)

Description

Basic Info.

| Model NO. | ET-360B |

| Certification | ISO |

| Panel Thinkness | 10-60mm |

| Min.length panel | 120mm |

| Min.width panel | 60mm |

| Manufacturing Principles | Glue Tank Underneath |

| Customized | Customized |

| After-sales Service | Video and Technology Provide |

| Total Power | 12.5kw |

| Net Weight | 1500kg |

| Transport Package | Plywood Box with Strength Film |

| Specification | 4700*925*1560mm |

| Trademark | ET |

| Origin | China |

| HS Code | 8465940000 |

| Production Capacity | 5000set Per Year |

Product Description

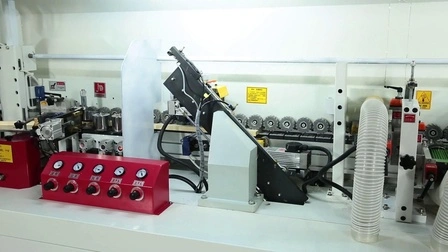

ET-360B Laminate Trimmer Wood Through Feed MDF Full Automatic Bevle Edge Banding Machine Price

1. Brief Introduction:

1) Used for different plate: MDF, block board, particle board, solid wood board, polywood, polymer plate, fire board etc.2) Banding edge for desks,carbinet,wardrobe and stright line furniture.3) Tape material can be PVC,melamine, veneer etc.4) Can save lots of labors and cost, especially suitable for suitable for medium and large scale users.5) Concentrated modern design for automatic woodworking production line.6) Factory direct produce and supplying

Color and design can be customizedPainting is baking paint after steel plate sanding.Strong frame and heavy duty machine, the designed life is 15 years.

2. Specification: ( can be customized)

| Model | ET-360B |

| Input Voltage | 380 V(220V,400V,415V etc) | |

| Edge Thickness | 0.4-3 mm | |

| Workpiece thickness | 12-55 mm | |

| Panel Length | Min.120 mm | |

| Panel Width | Min.60 mm | |

| Feeding Speed | 13 m/min | |

| Transport Motor | 1.5 kw | |

| Panel Preheating power | 0.3 kW | |

| Glue Melting Power | 1.5 kW | |

| Gluing Motor | 0.55 kw | |

| End-trimming Motor Power | 0.37 kw*2 | |

| Fine-trimming Motor Power | 0.75 kw*2 | |

| Polishing Motor | 0.18 kw*2 | |

| Total Power | 12.5 kw |

3. Features :

1) Multi-Fuction: Linear edge banding machine with Edge banding-end trimming--rough trimming--fine trimming--Contour Tracking-scrapping--buffing.

2) Gluing and edge banding: mechanism adopts glue melting device to gelatinize the plates and tape uniformly, meanwhile make sure they can be conglutinated firmly.3) End-trimming mechanism is to cut the forward and rear tape after gluing and press process by the movement of the precise guide track, it is with automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.4) Rough &Fine Trimming unit, with two individual high frequency motors, trim the exceeding edge on the top and bottom side of the panel, ensure both sides of the edge smooth and even.5) Contour Tracking Profiling unit is to make board end more smooth and aesthetic6) Scraping unit for a perfect finishing of the applied edge.7) Buffing unit is equipped with cotton polishing wheels to make smooth surface by end-polishing.

Case

4. Pictures and details 5.Relative Products

Product Name: PVC Edge BandingPVC Content: 75%,90% or as request Surface Treatment: Matt, Glossy, High Glossy, Embossed Color: Solid color, Wood Grain(Barma teak, Walnut, Birch etc.) One roll: 100m,200m,300m or as request Usage: Edge banding for furniture, Table Cabinet

6.Delivery and Package

1) No matter container shipping or LCL shipping, the machine will be packaged with standard plywood case and plastic flim rolling all around the machine for anti-dust.2) Usually, If have machine in stock, it can deliver 2 days after deposit, if no, can be deliver within 7 days after deposit.

7. About Us

Shandong Eterne Machinery Co.,Ltd. is a manufacturer based on woodworking machinery and equipment with high-tech products as direction.The research and development capabilities of new products have always been in the leading position. The products have always maintained the market position of high technical grade, good quality performance and reasonable cost performance.ET machienry had been exported to many countries of the world such as America, Russia, Indonesia, Uzbekistan, Algeria, Mongolia etc more than 20 countries. Eterne people make full use of technology and brand advantages, established a developed sales network throughout China, at the same time we established a good after-sales service network, can provide customers with quality technical advice and installation and maintenance services.

8.FAQ:

1. Are you manufacturer/Factory ?

Yes, we have two factories, one is mining machinery factory since 2015, another one is woodworking factory since 2003 and started to export since 2011, welcome to visit us. :)2. What is warranty?We provide 1 year warranty and life long maintain of our products.3. Is your machine can be customized according to client request?Yes, we have our own design team, can produce customized.4. What is the payment item?We accept T/T, L/C, Western Union ect and can also place the order on Alibaba.5. Where are you located?We are located in Weifang city, Shandong province, China, 3.5h far from Guangzhou by plane, about 1hour far from Qingdao City by train.6. How many countries had you exported?Although this is our new online plant form but our goods had been exported to more than 50 countries by other ways including USA,Russia, Columbia, Brazil, Argentina, Nigeria, Ghana, Congo, South Africa, Saudi Arabia, Kazakhstan, Bangladesh, Malaysia,Indonesia and so on.

Prev: 1 Color Sealed Ink Cup Pad Printing Machinery for Insoles/SD Card Pneumatic Pad Printer

Next: Plastic, Aluminum and Laminate Tubes Cream Ointment Cosmetic Tube Filling and Sealing Machine

Our Contact

Send now