Plastic Product Making Rotational Moulding Machine Rotomolding Machine for Water Tank Manual Plastic Moulding Machines

Description

Basic Info.

| Model NO. | BF-3500-2A |

| Control System | Siemens PLC |

| Raw Material | HDPE, LDPE, LLDPE |

| Oven Diameter | 4000*4000*4000mm |

| Power(W) | 40kw |

| Productivity | High |

| Weight | 18ton |

| Dimension(L*W*H) | 17*9*5.4m |

| After-Sales Service Provided | Field Installation, Commissioning and Training |

| Color | Customized Made |

| Delivery Time | 60 Days |

| Transport Package | Plywood Case, Rag-Rugs and PVC Film |

| Trademark | BENFAN |

| Origin | Zhejiang, China (Mainland) |

| HS Code | 8477401000 |

| Production Capacity | 10 Sets/Month |

Product Description

Product Introduction

Shuttle style rotational molding machine is placed along a straight line with oven and two mainframes in its center. Cooling chamber and loading station in both sides. When one arm on one side rotating the mold into the oven to get heated, the molds on other arm can be demoulded or adding material.In this way, the operation is flexiable for manufacturing comparatively large product. Even for comparatively small product, productivity is high. Besides, equipment is relatively simple and easy to be maintained. At present, this kind of rotational molding machine is broadly used in our country.

Benfan rotomolding machine advantage:

1. It only takes 3mins. from room temperature increase to 250 to 280 degree in oven

2. Arm is made of special alloy material which is good load

3. Full gear transmission, high efficiency

4. Full automatic operation,prognsis equipment trouble in advance and solve it in time.

5. Heavy duty oven and energy saving

6. Loading and unloading easy for mould

7. Special deep cavity heating technical, suitable for complicated product

8. Internet remote control (if the machine has problem in your factory, we can solve the problem through internet)

9. PLC and Motors are Siemens brand from German,Burner is RIELLO from Italy,Bearing is NSK from Japan, all electrial compenents are using Schneider brand.

10. Big computer screen, bob-weight system, special made motor, thermostability sealing arm head etc

11. Use circle oven, it is more uniform heat distribution on the mold, that means it is good for product making and also more energy saving.

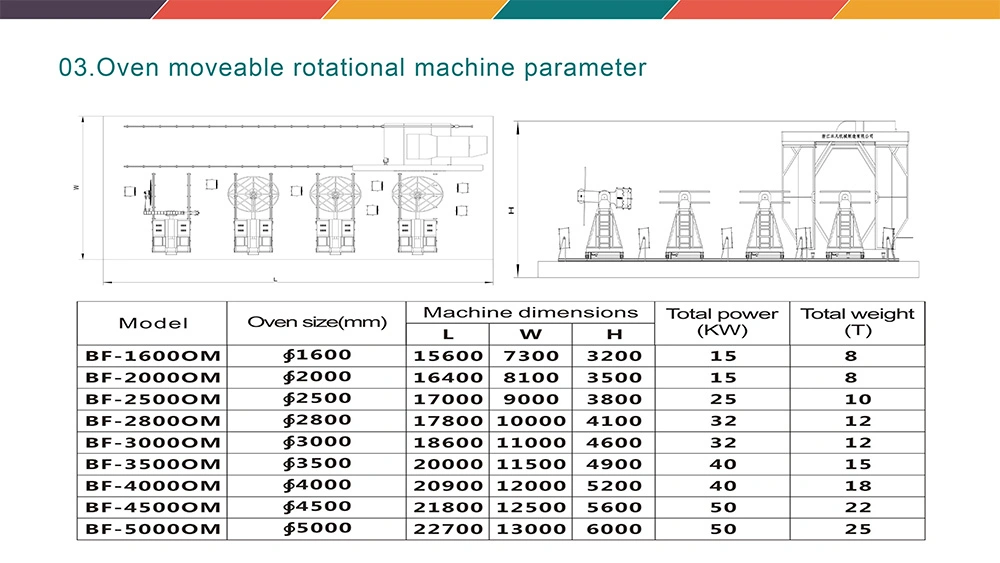

Technical parameters

Quick Details

Benfan Machinery Co., Ltd profiles Zhejiang benfan Machinery Co., Ltd. is a comprehensive company specializing in the R & D, manufacturing and sales of rotational molding equipment and rotational molding products. It has a number of patents in the industry and has always been in a leading position in China. Zhejiang benfan Machinery Co., Ltd. is located in Yuyue Town, Deqing County, Huzhou City. The company was established in 2010 with a registered capital of 30 million and more than 200 employees. The company's headquarters covers an area of 23000 square meters and a construction area of more than 65000 square meters. It has multiple production lines and adopts hierarchical management, so as to realize the assembly line operation from raw materials to finished products, and achieve efficient production while ensuring product quality. The branch covers an area of 5000 square meters and is specially used for equipment R & D. the company has a strong technical R & D team composed of senior engineers, design engineers and assistant engineers in plastics, machinery, automatic control and other industries.

FAQ

------------------------------------------------------------------------

Q1:What is rotomolding process?

A:The rotational molding process is quite simple: A hollow mold is filled with powdered plastic resin. The mold begins rotating bi-axially and is transferred into an oven. The mold continues to rotate as the resin melts and coats the walls of the mold. The mold is cooled until the resin hardens into the desired shape.

Q2:What materials are used in rotational Moulding?

A: Rotomolding Materials Include:

- Linear Low Density Polyethylene (LLDPE)

- Medium Density Polyethylene (MDPE)

- High Density Polyethylene (HDPE)

- Low Density Polyethylene (LDPE)

- Cross Link Polyethylene (XLPE)

- EVA Co-polymer (EVA)

- Polyvinylchloride (PVC)

- Nylon.

Q3:How many types of rotational Moulding are there?

A:The types of rotational molding equipment are turret machines, shuttle machines, rock and roll machines, and open-flame machines.

Q4:Whats your companys' main products?

A:Our company is specialized in the rotational molding machines, moulds,Ice cooler box .

Q5. What is your delivery time?

A:Usually within 60 working days after sign contract and upon receipt of deposit TT transfer.

Q6. What is your payment terms?

A:50% deposit TT transfer after sign contract, and balance 50% after inspection before shipment.

Q7. How about your warrant and after-sale services?

A:All equipment unit are service one year warranty,

For electrical motor, Inverter, and PLC, we offer warranty for 18 months.

Q8. Do you test all your machine before delivery?

A: Yes, we test 100% of machine by our engineers before leave our company.

Q9. How to install and trial run when machine arrive customer's factory?

A: Due to epidemic, we could not send our technician abroad, So, now, all the

exporting equipment are designed with module function, The buyer can install the equipment

with our installation instruction easier.

If the client insists to send the technician for machine installation, they will need to pay the travel fee and accommodation fee, and labor cost USD 100 for one person in one day. Welcome to enquiry us! Rotate your business,Snowball your wealth!

Our Contact